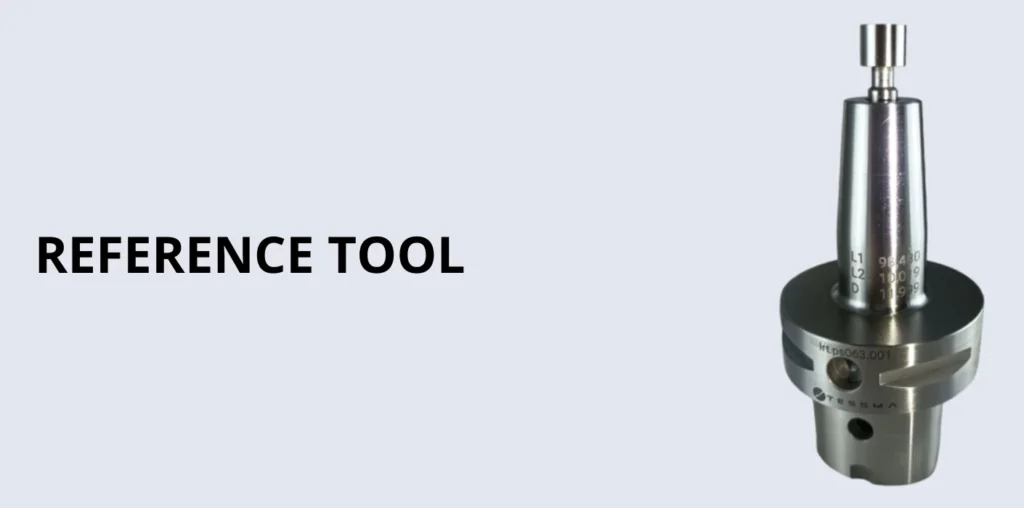

Your expert for precision tools.

We offer a wide range of high-quality, affordable precision tools for the machine spindle interface. Contact us.

Fast Delivery

Quick shipping of precision tools to your location, so your production stays on schedule.

24/7 Support

Our experts are available around the clock to answer your questions and solve problems.

High Precision

Tools engineered to the highest standards for exact measurements and optimal performance.

Your Expert For Precision Tools.

Your competent partner for precision tools all around industrial measuring

technology. We offer a wide range of high-quality precision tools at fair

prices around the machine spindle interface.

Available Interfaces:

ISO 7388-1 | ISO 7388-2 | ISO 7388-1 double contact | ISO 7388-2 double contact | ISO 12164 HSK Form A, C, E, F | ISO 26623-1 Polygone | ISO 10889 VDI | DIN 228-1 Morse Taper

Our experienced team will also take care of your special needs and offer

tailor-made solutions.

Range of services

Where others talk about "niche products," we speak of core competence: Measuring plugs and setting gauges, clamping force testers and alignment gauges, adapters and blanks......

Innovative orientation

TEssMa believes that problems are meant to be addressed and solved. During the operational process surrounding your machine spindle interface, a wide variety of requirements.....

Competent advice

Drawing on our many years of experience, we pinpoint manufacturing problems, identify any missing precision tools, and, upon request, supply you with the right product....

Price-performance ratio

Especially when it comes to precision, the term "cheap" should be banished from the vocabulary. Instead, it's about a fair price-performance ratio so that you remain...

Outstanding quality

Your customers demand the highest dimensional accuracy – and TEssMa supports you in this. By using TessMa measurement technology around the machine spindle interface....

24/7 customer service

Drawing on our many years of experience, we pinpoint manufacturing problems, identify any missing precision tools, and, upon request, supply you with the right product....

Our Products

Setting gauges

Setting gauges are precision instruments used to check, calibrate, and maintain exact measurements in industrial and mechanical applications. They ensure consistent quality, reduce errors, and provide reliable verification across a wide range of production and assembly processes, making them indispensable tools for precision engineering.